In precast, hollow, or ribbed slabs, part of the space that would otherwise be occupied by the concrete is left empty or filled with a material of less weight, such as ceramic bricks or expanded polystyrene.

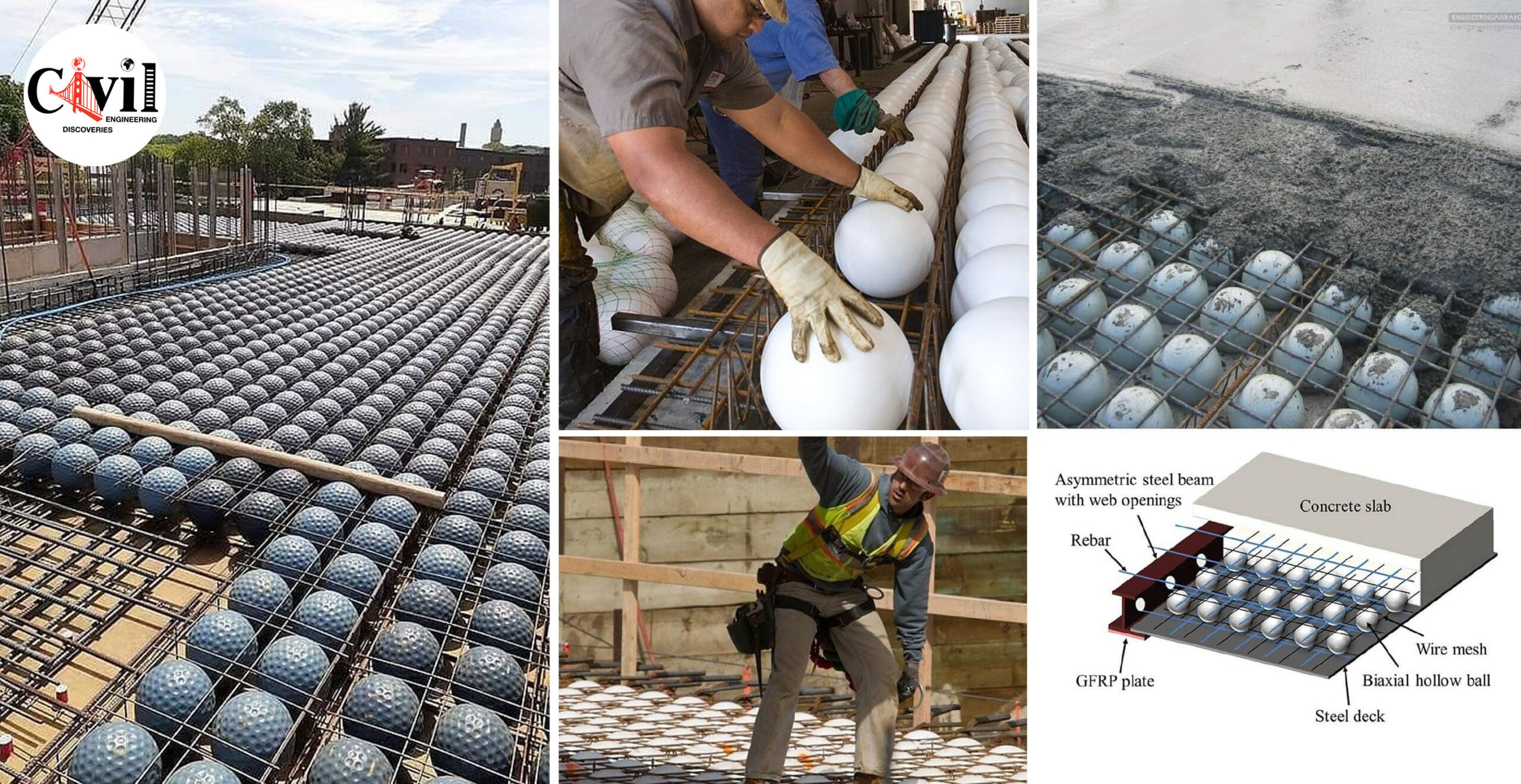

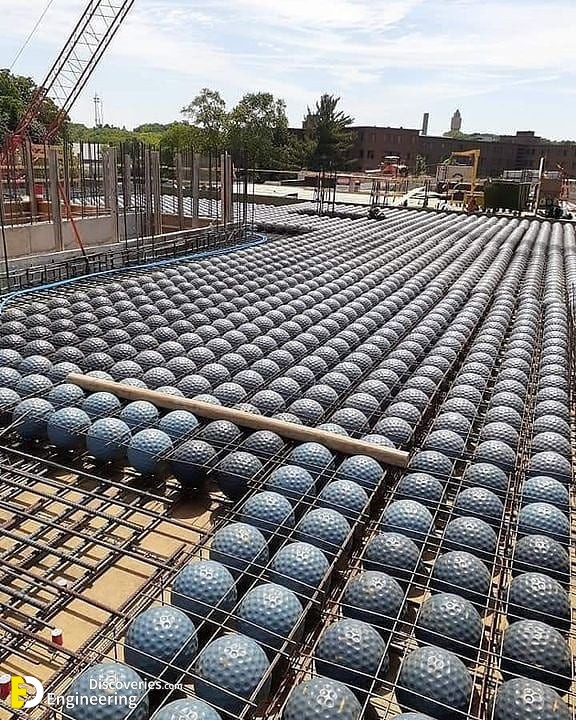

A similar approach was developed in the 1990s by Jorgen Bruenig, who developed in Denmark a type of biaxial hollow slab (today better known by the BubbleDeck trade name). It is a system composed of hollow spheres made of plastic, which occupy places where the concrete has a less important structural function, such as in between columns. The spheres, inserted uniformly between upper and lower steel reinforcements, fill with air the space that would otherwise be occupied by concrete serving little structural function and adding significant weight.

With this system, it is possible to reduce between 25% and 35% of the slab’s own weight (compared to a solid slab of the same thickness), allowing for larger spans, reducing the section of the columns, and decreasing overload on the building’s foundations. It is estimated that the use of 1 kg of plastic for the spheres saves about 100 kg of concrete.