The column is a long cylindrical member subjected to axial compression. Column carries self-weight and loads coming on it. Generally, load transfers through its longitudinal direction. The column is categorized based on its height. Every material used in the building experience both compression and tension stress that’s how we designed the modern buildings. Columns consist of two major material one is the concrete and the second one is steel. Architects do calculate the total stress caused by the live and dead load of the entire building and will design the internal components (foundation, beam, and columns) of the building. So if the applied stress exceeds allowable stress (calculated) then structures start to fail.

Types of Column Failure

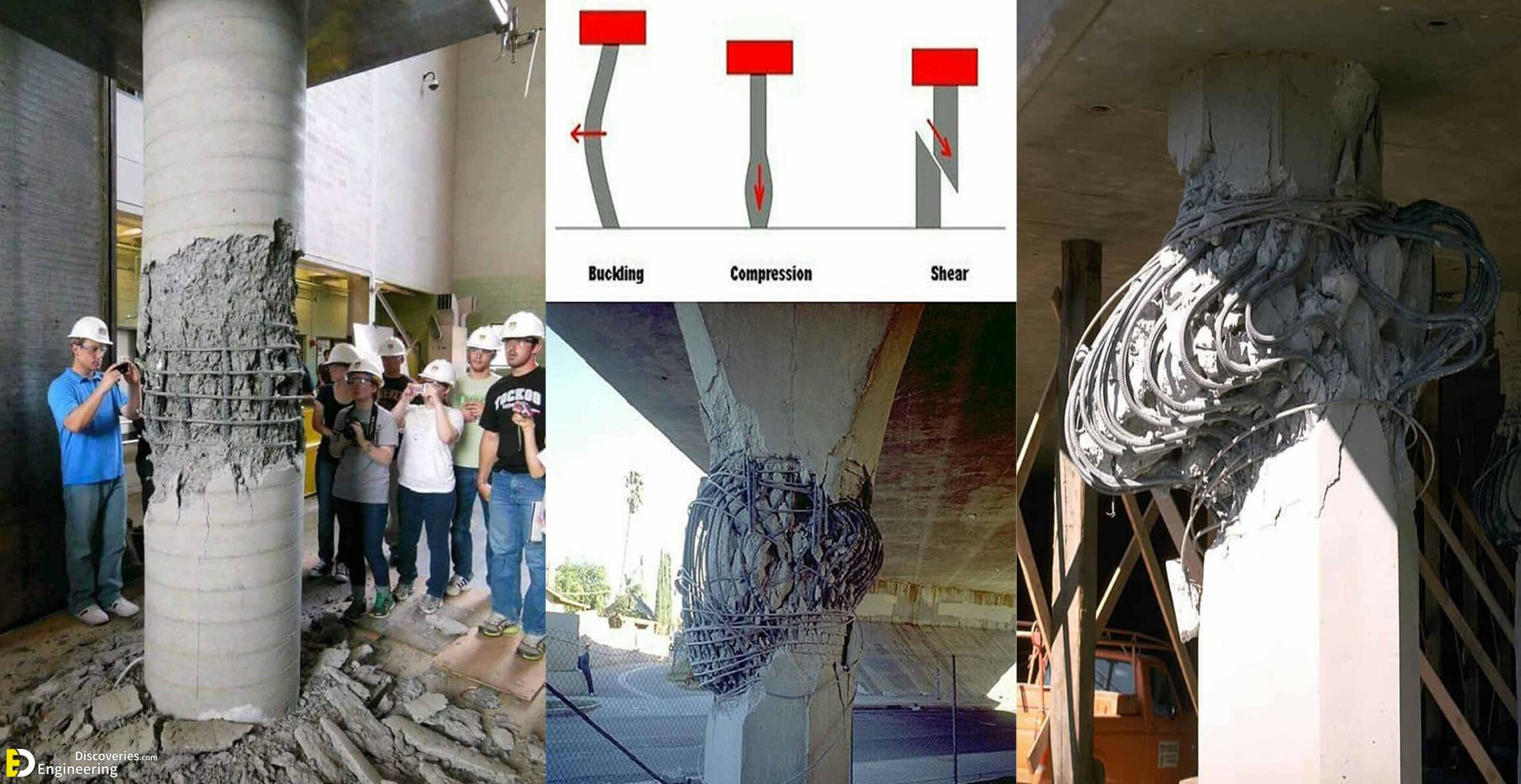

1- Compression Failure

2- Buckling Failure

3- Shear Failure

1- Compression Failure

When columns are axially loaded, the concrete and steel will experience some stresses. When the loads are greater in amount compared to the cross-sectional area of the column, the concrete and steel will reach the yield stress and failure will be starting without any later deformation. In this type of failure, the material fails itself, not the whole column. This type of failure mostly occurs in shorter and wider columns. To avoid this, the column should be made with a sufficient cross-sectional area compared to the allowable stress.

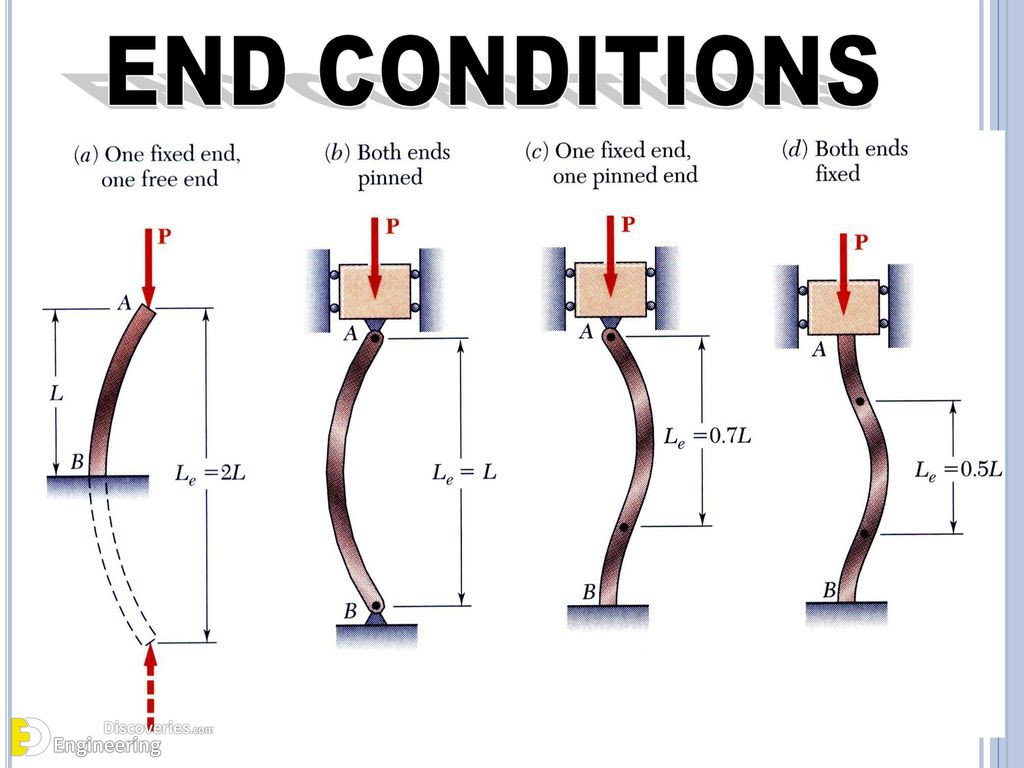

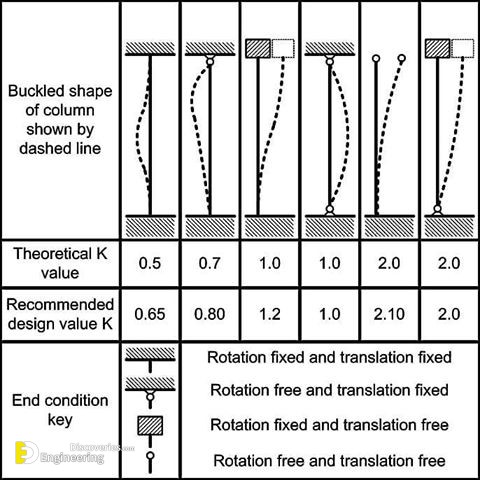

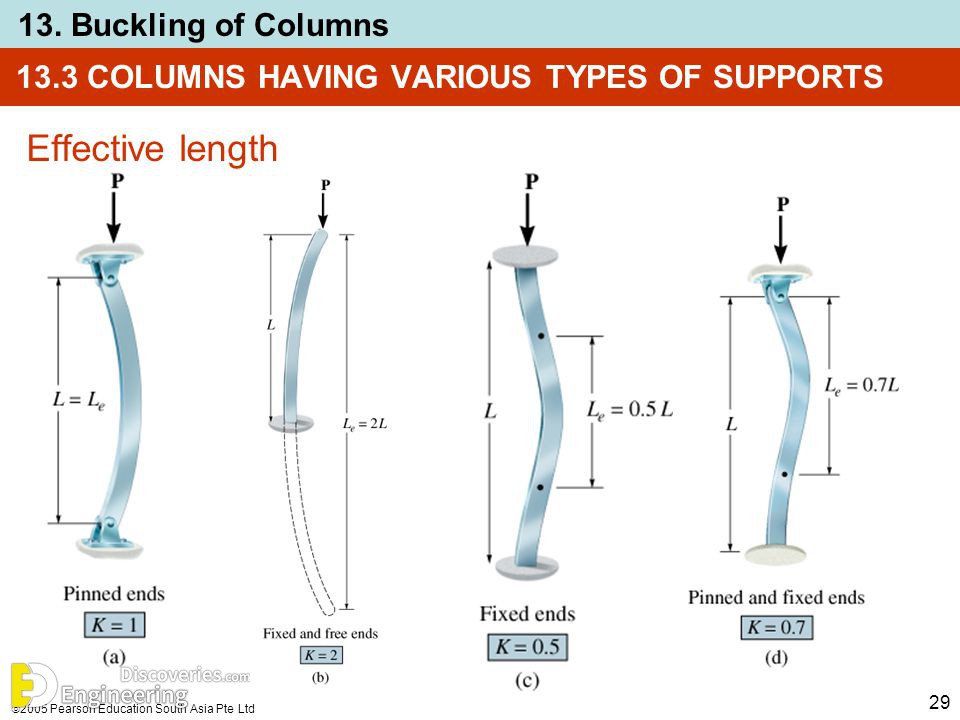

2- Buckling Failure

Buckling failure generally occurs in long columns. Because they are very slender and their least lateral dimension is greater than 12. In such a condition, the load-carrying capacity of the column decreases very much. The columns tend to become unstable and start buckling to sideward even under small loads. That means the concrete and steel reached their yield stress for even small loads and start failing due to lateral buckling. This type of failure can be avoided by not constructing long columns of slenderness ratio greater than 30.

3- Shear Failure

In engineering, shear strength is the strength of a material or component against the type of yield or structural failure where the material or component fails in shear. A shear load is a force that tends to produce a sliding failure on a material along a plane that is parallel to the direction of the force.

For more information watch this video